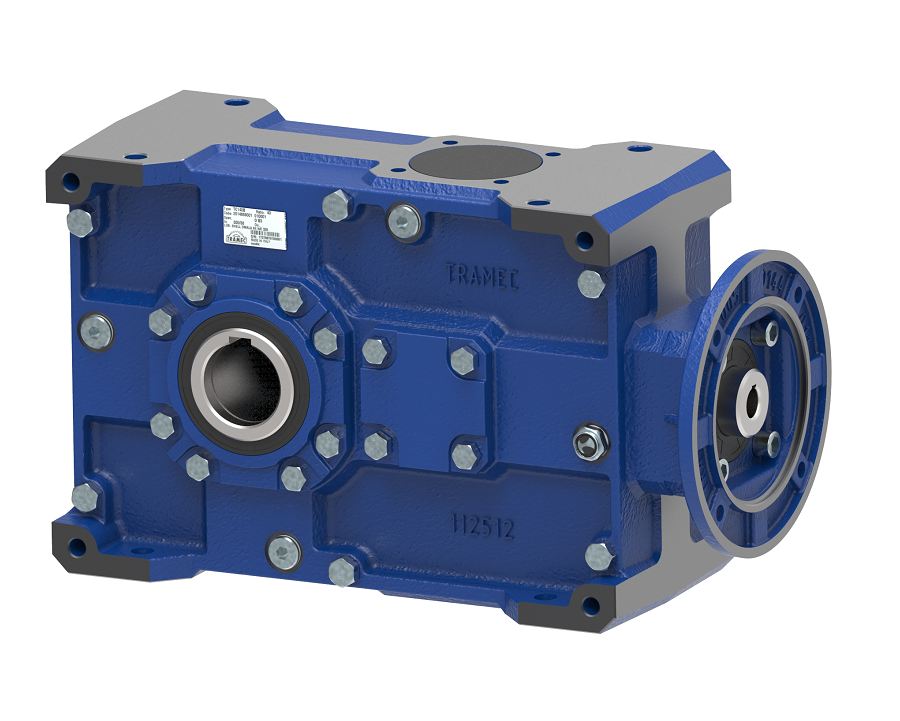

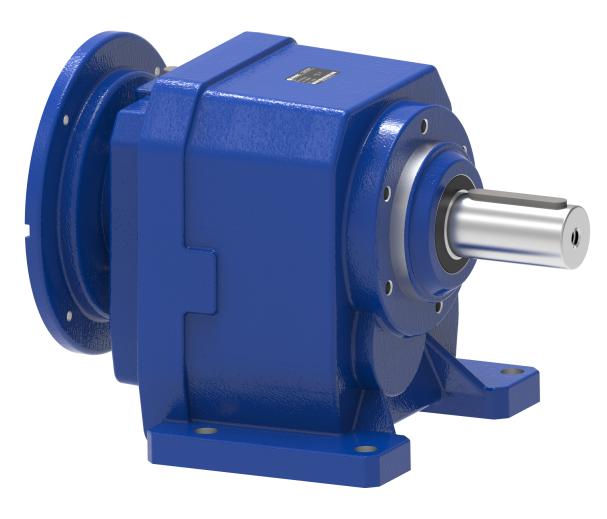

Coaxial helical gearboxes

Coaxial helical gearboxes

VARMEC gear reducers and motor- reducers have been entirely designed using leading edge technical computer software. Each single component has been designed and tested considering the maximum loads applicable to the reducer in compliance with AGMA 2001-B88

Main features are:

- modularity

- compactness

- universal mounting

- high efficiency

- low noise level

- hardened and tempered steel gears

- unvarnished aluminum casings in sizes 141 – 191 – 162 – 202A – 252A – 253A – 302A – 303A, varnished high resistance cast iron casings in other sizes

- input and output shafts in high resistance steel

The manufacturing process of the various components is made with modern CNC machinery that gives maximum precision construction. All gears are made from hardened and tempered alloy steel with successive corrections to increase performance and reduce noise levels even while running with a load.

VARMEC gearboxes are available in 4 sizes (141-191/241-281-381) for the types with only one stage of reduction and in 9 sizes (162-200- 250-300-350-450-550-580-600) for the types with two and three stages of reduction.

PRODUCT DETAILS:

- Input power from 0,09 to 54 kW

- Torque from 15 to 3000 Nm

- Reduction from 1:1,2 to 1:317

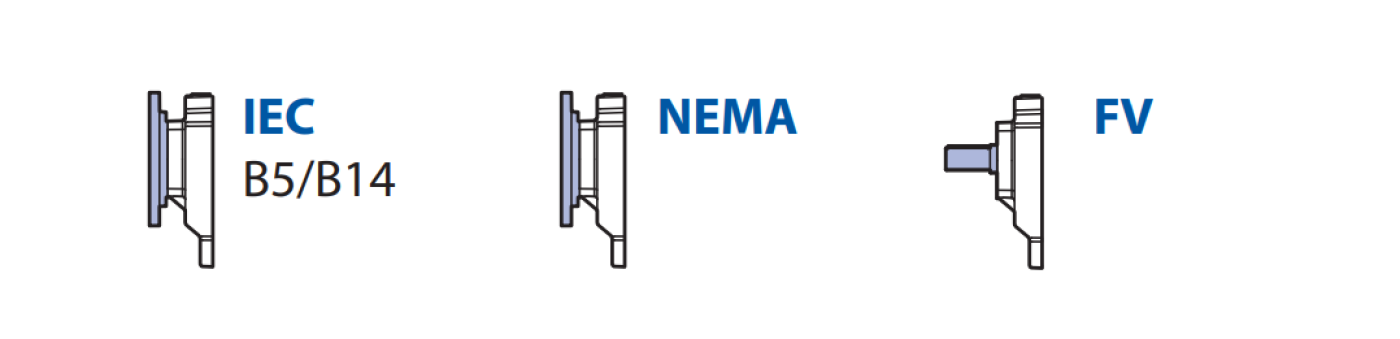

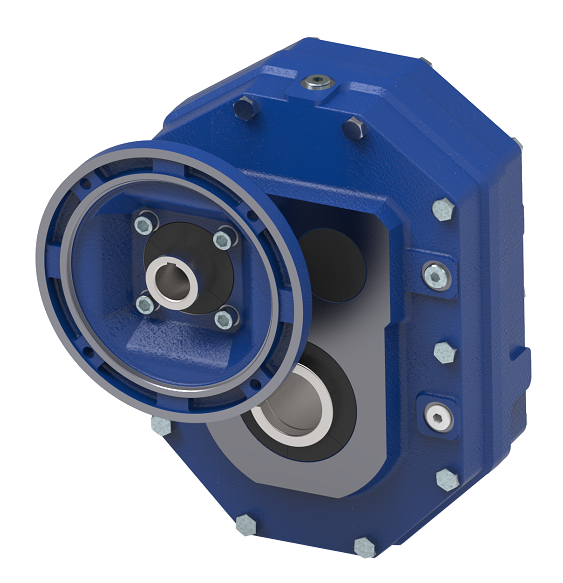

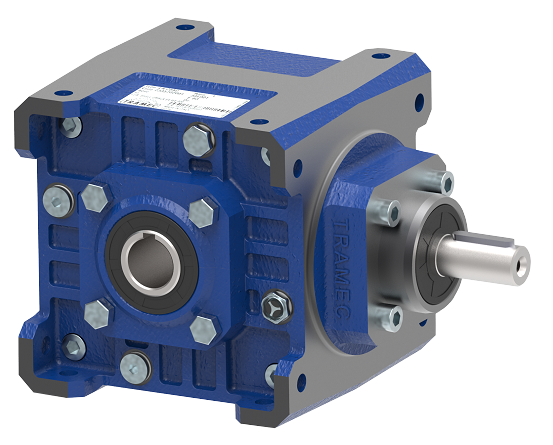

Every gearbox can be supplied with IEC input flange (RCV) for IEC electric motors or in the solid input shaft (CV) version. Input flanges NEMA are also available. A wide variety of output shaft diameters are available for each gearbox size.